DISSEMINATION NEWSLETTER July 2020

ReCollect - Efficient Manufacturing of Recyclable Composite Laminates for Electrical Goods – No 34163

The ReCollect project is funded by Innovate UK, part of UK Research and Innovation. It began in October of 2019 and is intended to run for 30 months.

Normally, the ICT would be holding events which could be used to disseminate the latest information on the project, but during the Covid-19 lockdown, we are using this on-line vehicle to ensure that the Industry is kept up to date.

Innovate UK is the UK’s innovation agency. Innovate UK works with people, companies and partner organisations to find and drive the science and technology innovations that will grow the UK economy - delivering productivity, new jobs and exports. The aim at Innovate UK is to keep the UK globally competitive in the race for future prosperity.

PARTNER ORGANISATIONS:

LEAD PARTNER

Established in September 2017, Jiva Materials Ltd is a sustainability start-up based in London, UK.

Jiva, as the inventor of Soluboard, will lead the specification and development of the thermoplastic input materials, as well as the conversion of the substrates into working circuit boards. Jiva will also coordinate the project.

DEVELOPMENT PARTNER

Coventive Composites is a specialist independent consultancy, providing technical expertise and access to pilot-scale equipment and testing facilities to help our clients develop and commercialise novel composite materials and components. Our expert advice and technical support cover all aspects of the product development lifecycle.

DISSEMINATION PARTNER

The ICT facilitates dissemination of knowledge and expertise by a series of seminars and symposiums in varying locations throughout the UK. The ICT Quarterly Journal contains papers and information regarding novel processes and techniques and they also offer an annual Foundation Course in PCB manufacture and design. This is a valuable source of information for both novices and more advanced engineers wishing to widen their knowledge and experience of the application of cost effective and reliable processes and techniques.

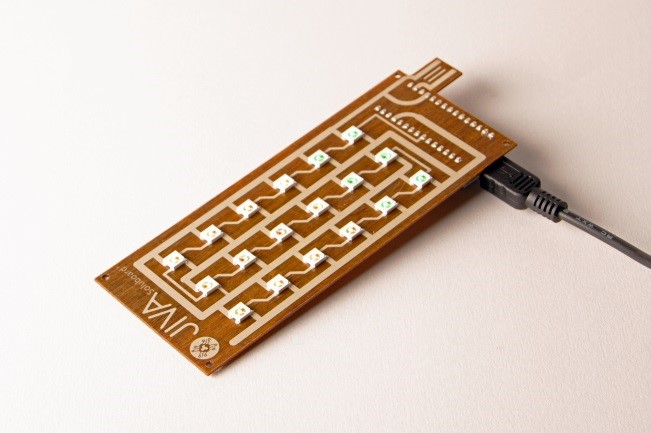

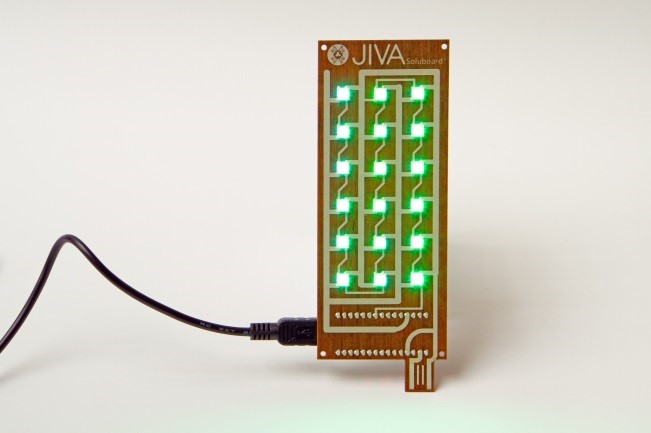

Review of progress at our last evening event

At the end of the second quarter, Dr Jonathan Swanston, chief technical officer with Jiva Materials, gave an update on the ReCollect project and explained the background to the development of the world's first fully recyclable PCB laminate. He passed-around samples of his material, composed of a natural fibre bound with a polymer soluble in hot water but not in cold water, which had the appearance of a light-brown-coloured unclad laminate.

Dr Swanston reviewed some statistics which indicated that PCBs made up 8% of the 50 million tonnes of electronic waste that was generated in 2018. The ReCollect project explored an alternative way of managing end-of-life circuit boards. Currently, the only practical way of recycling glass-epoxy circuit boards involved shredding and incineration to recover the metal content. The ultimate aim of the project was to remove glass-epoxy boards from the supply chain, by demonstrating that Jiva’s Soluboard® could match the performance of CEM-1 and FR-4 materials.

He explained that Soluboard® was a fully biodegradable and non-toxic product based on flax. A primary aim of the project was to demonstrate the feasibility of producing the material in high volumes at a competitive price, using a continuous-production process in development by Coventive Composites.

The nature of Soluboard® was to delaminate when immersed into hot water, enabling the flax fibres to be composted or repurposed and the electronic components to be removed for re-processing. Silver printing was a feasible method of creating functional circuits, but in order to use existing aqueous manufacturing processes it was necessary to seek a means of chemically protecting the material in-process, and this was part of the project.

Dr Swanston commented that “white goods” – large household appliances – constituted more that 30% of e-waste, and that the Global E-Waste Monitor had reported that less than 20% of this was documented as collected and recycled. The rest went to landfill. Jiva intended to push for the safe recovery of e-waste in line with the WEEE2 Directive. The white goods market was their initial target, and specifications from potential customers had defined electrical, flammability and mechanical requirements. Soluboard® had a Tg of 126°C and a UL94V0 flammability rating. Its electrical properties were being determined by a third-party laboratory and final results were awaited. As part of the project, functioning populated PCBs would be designed, manufactured and evaluated as specified by end customers.

|

|

We intend to update this newsletter as a monthly link to our website as a way of keeping the project in the Industry's in-tray, during the lockdown.